Contact us

Phone: +86-13001445333

WhatsApp: +8613001445333

Chengnan Industrial Park, Dongguang County, Hebei Province, China

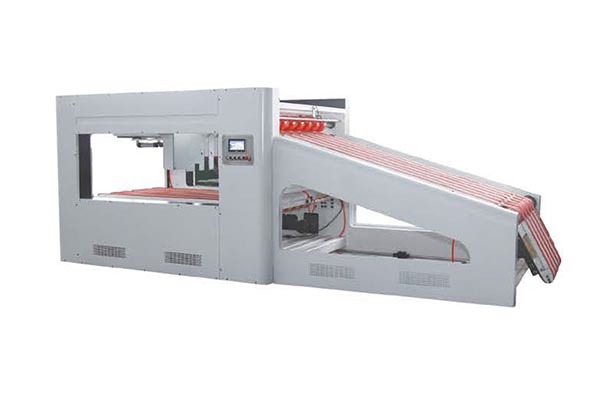

SODJ-2200 Double-piece automatic nailing box machine

- 产品描述

-

Main Features

● The whole machine control system is the company and Huichuan servo jointly developed double automatic nail box machine special control system, the whole machine control system adopts Huichuan servo closed- loop control system, all servo motors are high precision absolute motor, so this system is characterized by high precision, fast reaction speed, good compatibility;

● All electrical control systems are integrated into a control cabinet with temperature control to reduce poor communication due to mechanical vibration;

● The whole set of nail heads are made of special steel and CNC precision machining; Using swinging nail head, fast speed; Wire feeding adopts servo wire feeding device.

● Bottom die, blade made of German tungsten steel (wear-resistant);

● Nailable lidless box; (Please specify when ordering);

● One machine dual-use, can nail a single piece of nailing carton, double piece of nailing carton;

● Switch between reinforcing nails, single nails and double nails without stopping; (Reinforcing nail is optional)

● Stacking department automatic counting output, finished products sent to facilitate bundling; (High speed falling stacker is optional)

● The machine uses the computer screen to display the fault description; (Online fault detection is optional)

● The machine adopts automatic wire feeding system, no wire alarm, 20KG plate flat wire, saving time;

● Suitable for large and small cartons, fast and labor-saving;

● Suitable for corrugated cardboard three layers, five layers, seven layers (seven layers need special instructions).

Product Parameters

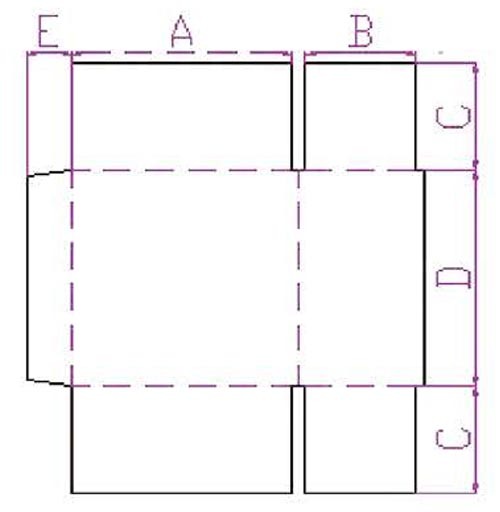

Model SQDJ-2200 SQDJ-3200 SQDJ-4200 Max.size(mm) (A+B) 1100 1600 2100 Max.size(mm) (A+B)×2 2200 3200 4200 Min.size(mm) (A+B)×2 600 Max.size(mm) (C+D+C) 1200 Min.size(mm) (C+D+C) 300 Max.width(mm)B 500 800 1000 Min.width(mm)B 200(120) Nailing From (mm) 30-200(High speed) Number of Nails 2-99 Speed(Nail/minute) 750-1000 Weight (T) 20T 25T 30T

Feed section

● The paper feed motor is driven by servo motor, the system is noiseless, the speed is flexible and stable.

● This part adopts the left and right double servo paper feeding mode, the adjustment is stable, efficient and accurate.

● The leading edge paper feeding part is automatically adjusted, suitable for various specifications of carton paper supply needs, convenient and fast.

● Equipped with side slapping device to ensure that the paper is not skewed.Nail the box part once

● The leading edge will feed the cardboard into the primary nailing box, and tap into the front side of the nailing box. The nailing mouth of the primary nailing box will be fine-tuned and controllable to meet the standard requirements.

Folded part

● Linkage with paper supply, frequency conversion speed regulation.

● The use of imported porous belt conveyor cardboard, automatic folding, the whole process adsorption, the secondary rolling device effectively avoid the phenomenon of skewed slip pile paper in the work of a variety of cardboard boxes, laminated boxes, glazing boxes, etc., so that the machine is more stable and efficient, rolling line is more accurate.Correction part

● The machine will have a shaping device at the end of the folding part and before nailing the box for a second time. Before nailing the box, the folded carton will be simulated by hand again for rounding and patting to ensure that the nailed carton has no scissors.

● The correction part is driven by servo motor and completes the shaping action of belt, push plate, baffle and cylinder.

Counting, stacking output department

● After the nail box department completes the carton, the counting and stacking department automatically sends it out and packages it.

Keywords: