Contact us

Phone: +86-13001445333

WhatsApp: +8613001445333

Chengnan Industrial Park, Dongguang County, Hebei Province, China

Automatic folder gluer machine

- 产品描述

-

Features

The automatic folder gluer is composed of three parts: the vacuum paper feeding part, the gluing and folding part, and the counting and stacking output part, Digital display control, PLC computer adjustment, and double frequency conversion synchronous operation have a simple. fast, reliable, and accurate control mode. Automatic paper feeding, automatic qluing and folding, automatic counting automatic stacking output, synchronous bel paper feeding, diferential adjustment,remote control within 100 meters to realize remote host start and stop, host acceleration and deceleration, fan sta and stop, paper feeding start and stop, Emergency stop,left and right arm adiustment, gluing box adiustment, average gluing speed of 230 m/min, high speed, energy saving, labor cost saving. it can stick large and special-shaped cartons, such as TV boxes, saving labor and achieving high efficiency.

Product Introduction

● Adopting belt suction and paper feeding method, accurate and reliable.

● Adopt high-grade electromagnetic clutch and electromagnetic brake system so that the paper feeding part can be controlled independently and the operation is simple.

● The pressure roller is linked with the folding part, the height is adjustable, and it is suitable for the thickness of the cardboard of 2 - 8mm.

● The paper feeding wheel is linked with the folding part, the speed is controlled by frequency conversion, and the paper feeding speed is 230m/min.

● The front fence of the paper feed section and the paper feed belt are adjustable left and right.

● The main motor adopts a frequency conversion speed regulation system with no noise and flexible and stable speed regulation.● Imported high-friction belts are used to transport the cardboard, and it is automatically stacked.

● Using stainless steel wheels to apply glue, the glue is even, trouble-free, and glue-saving.● The folding part is equipped with a cardboard correcting device and an indentation correcting device.

● There are two rows of an adjustable inner positioning guide wheel system in the folding part, which has higher forming precision.

● Folding speed: 0-230m/min

● The paper feeding belt is conveyed by a synchronous belt and synchronous pulley to prevent the belt from slipping, and the paper feeding is accurate and reliable.

● Automatic stacking and neat output.

● The main motor of the counting part is frequency-controlled, the speed is adjustable, and the start-up is stable and reliable.

● The cartons are conveyed by the belt, stacked neatly, and the speed is 0-230m/min.

● Use the flapping board to align the cartons with the function of correcting the deviation, and the deviation is very small.

● Pneumatic method is used for counting and ejection; PLC electric control ensures reliable action, accuracy, and speed.

● It adopts a PLC programming controller and touch-screen digital control,which are easy to operate, reliable in action, input data without stopping, and automatically count.

● The output part adopts the synchronous pressing method of the bottom conveyor belt and the upper pressing belt, so that the finished cartons are firmly bonded and output neatly.

● Adopting belt suction and paper feeding method, accurately and reliably adjusting with servo differential, which can forcibly and effectively correct phenomena such as fish tail mouth scissors difference.

Specifications

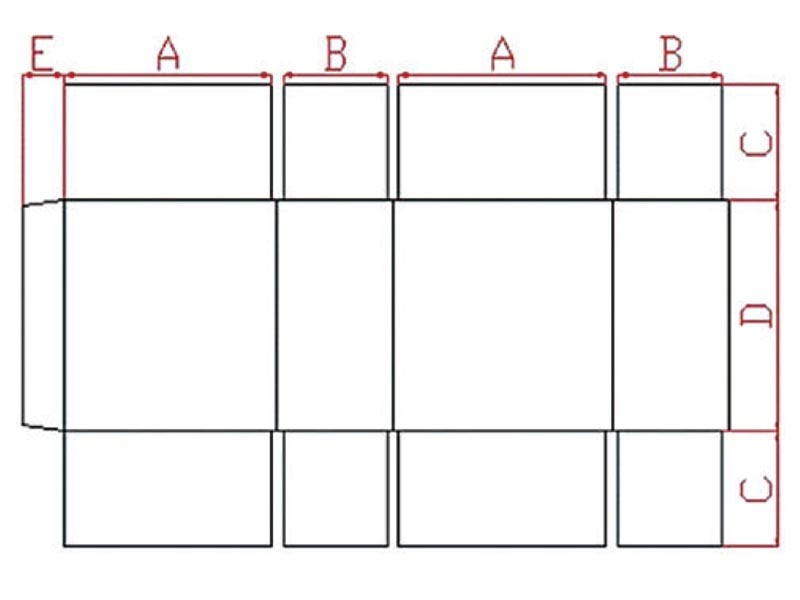

Model QZD-2900 Dimension A (mm) 80-690 Dimension B(mm) 80-690 Dimension A+B(mm) 180-1300 Dimension C(mm) 40-345 Dimension D(mm) 90-1120 Dimension C+D+C(mm) 170-1200 Dimension (A+B)×2 420-2550 Device Dimension (mm) 3500x11000 Installation area (mm) 4200-15000 Motor power (KW) 12KW

Keywords: